A Complete AI-Guided Precursor Optimization Architecture for a Reaction-Flavor R&D Platform

Below is a complete AI-guided precursor optimization architecture for a reaction-flavor R&D platform.

This is designed to:

- Optimize sugar/amino/sulfur/lipid ratios

- Control reaction conditions

- Predict volatile output

- Link GC-MS + sensory data

- Autonomously improve formulations

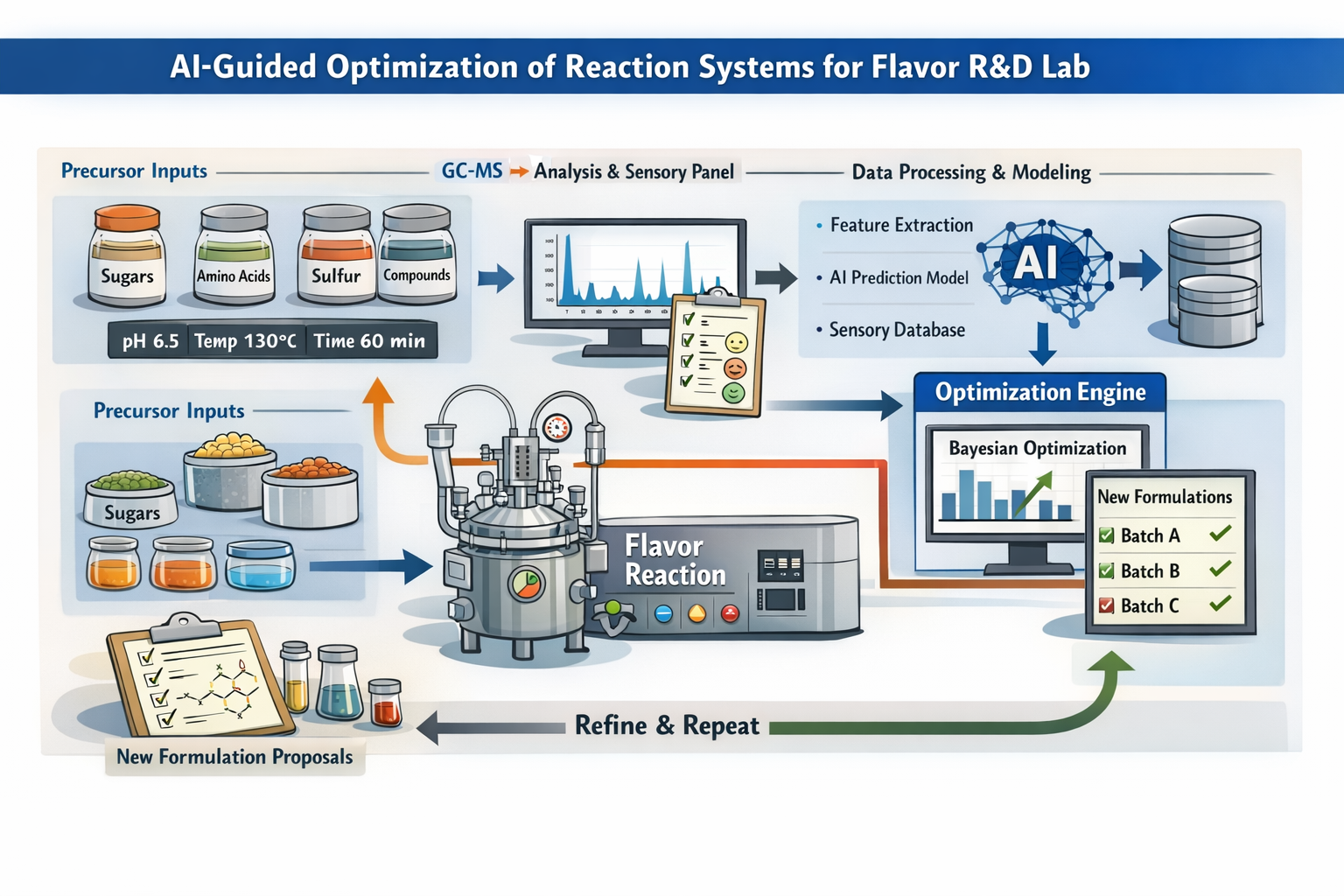

🧠 SYSTEM OVERVIEW

We build a closed-loop system:

Formulation → Reactor → GC-MS → Feature Extraction →

Prediction Model → Optimization Engine → New Formulation

The goal:

Maximize sensory score for a defined target profile under cost + regulatory constraints.

1️⃣ DATA STRUCTURE FOUNDATION

Every reaction run must generate structured data.

A. Input Vector (X)

For each batch:

Chemical Inputs

- Sugar types (%)

- Amino acids (%)

- Sulfur donors (%)

- Thiamine (%)

- Lipids (%)

- Moisture (%)

Process Variables

- pH

- Temp ramp curve

- Total time

- Oxygen %

- Pressure

Total features: ~40–80 numeric variables.

B. Output Vector (Y)

Analytical Data

- GC-MS peak intensities

- Retention index

- Key marker compounds (e.g., 2-furfurylthiol, 2-acetylpyrazine)

- Total sulfur volatiles

- Pyrazine index

Sensory Panel Scores

- Roasty (0–10)

- Meaty

- Sweet

- Sulfur intensity

- Burnt

- Authenticity

- Overall liking

2️⃣ FEATURE ENGINEERING LAYER

We do not feed raw GC-MS directly.

Instead:

Extract Chemical Descriptors

Examples:

- Total pyrazine area

- Strecker aldehyde ratio

- Sulfur compound cluster score

- Furan index

- Lipid oxidation aldehyde score

These become engineered features.

3️⃣ MODELING LAYER

We use three model tiers.

Tier 1: Forward Prediction Model

Predict:

(X: formulation + conditions) → (Y: volatile + sensory profile)

Best models:

- Gradient Boosting (XGBoost)

- Random Forest

- Neural Network (if dataset > 1000 runs)

Outputs:

- Predicted GC profile

- Predicted sensory vector

Tier 2: Inverse Optimization Model

Goal:

Find X that maximizes a target sensory profile.

Use:

- Bayesian Optimization

- Gaussian Process Regression

- Genetic Algorithm (multi-objective)

Objective example:

Maximize:

0.5*Roasty + 0.3*Authenticity + 0.2*Sweetness

- 0.4*Burnt

Under constraints:

- Cysteine < 10%

- Cost per kg < $12

- No restricted precursors

Tier 3: Reaction Pathway Awareness Model (Advanced)

Add chemical rules:

Example constraints:

- Pyrazines ↑ when pH > 7

- Sulfur harshness ↑ when cysteine > 12%

- Ribose increases meatiness exponentially

This can be encoded via:

- Rule-based modifiers

- Hybrid physics-informed ML

4️⃣ CLOSED-LOOP OPTIMIZATION SYSTEM

Workflow:

Step 1

Define Target:

"Chicken roast authentic, moderate sulfur, low burnt"

Step 2

AI proposes 5 candidate formulations.

Step 3

Reactor runs 5 batches.

Step 4

GC-MS + sensory panel input.

Step 5

Model retrains.

Step 6

New optimized proposals.

Repeat until convergence.

5️⃣ MULTI-PROFILE LEARNING

Instead of training separate models:

Use shared chemical backbone learning.

The model learns:

- Core Maillard behavior

- Sulfur chemistry

- Lipid oxidation trends

Then fine-tunes for:

- Coffee

- Beef

- Maple

- Popcorn

This dramatically reduces data requirements.

6️⃣ ACTIVE LEARNING STRATEGY

Rather than random experiments:

AI selects experiments that maximize information gain.

It chooses:

- Edge-of-boundary sulfur levels

- Novel sugar combinations

- Extreme pH conditions

This reduces required experiments by 40–60%.

7️⃣ VOLATILE TARGETING MODE

You can also invert the system:

Instead of "maximize sensory roast", you can target:

- 2-Furfurylthiol = X ppm

- 2-Acetylpyrazine = Y ppm

- DMTS < threshold

The optimizer finds precursor ratios that hit chemical targets.

8️⃣ COST-AWARE OPTIMIZATION

Add:

Total Cost = Σ(precursor cost × %)

Then optimize for:

Max Flavor Score / Cost Ratio

Useful for commercialization.

9️⃣ PLATFORM ARCHITECTURE

Backend

- Python

- PyTorch or XGBoost

- Bayesian optimization library

- SQL database

Hardware Integration

- Reactor API

- GC-MS export API

- LIMS integration

🔟 DIGITAL FLAVOR TWIN

Eventually:

Create a digital twin of your reactor system.

Simulate:

- Reaction curves

- Volatile formation kinetics

- Sensory projection

AI can run 10,000 virtual experiments before 5 real ones.

1️⃣1️⃣ STRATEGIC ADVANTAGE

This turns your R&D from:

Trial-and-error chemist intuition

into:

Data-accelerated flavor discovery engine.

This is exactly how:

- Firmenich (now part of DSM-Firmenich)

- Givaudan

- IFF

are modernizing reaction flavor development.

But most mid-size flavor houses do not yet have a fully integrated closed-loop AI-reactor system.

###