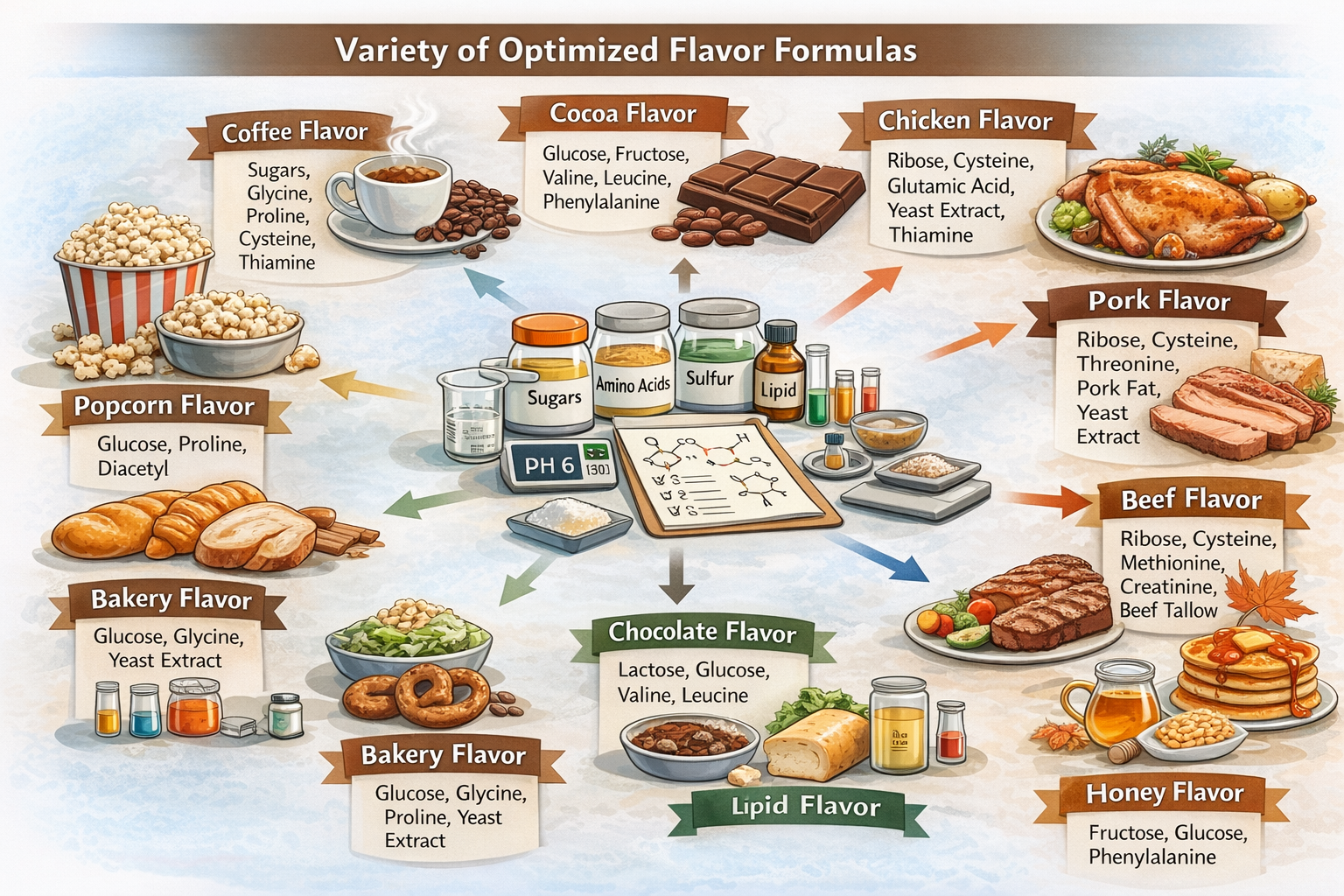

Practical, flavor-industry style optimized Maillard / thermal reaction systems for coffee, cocoa, chicken, pork, bakery, beef flavor, chocolate, cabbage, popcorn, maple flavor and honey

Below are optimized reaction systems for coffee flavor, cocoa flavor, chicken flavor, pork flavor, bakery flavor, beef flavor, chocolate flavor, cabbage flavor, popcorn flavor, maple flavor, honey flavor, provided by AI. Note that the reaction systems are incomplete in terms of the ingredients that are needed for a specific flavor.

These are practical, flavor-industry style optimized Maillard / thermal reaction systems for each target profile.

These are designed for controlled reaction flavor generation (paste reactor or pressure vessel), not for uncontrolled kitchen cooking.

The AI agency structure each system as:

• Key precursors

• Functional enhancers

• Recommended ratios

• Reaction conditions

• Expected key impact molecules

• Process control notes

1️⃣ COFFEE Flavor Reaction System

Objective

Roasty, coffee, slightly sulfurous, cocoa-like top notes.

Core Precursors

- D-Glucose

- L-Cysteine

- L-Proline

- Glycine

- Thiamine (trace)

Optimized Formula (% dry basis)

- Glucose – 40%

- Glycine – 20%

- Proline – 10%

- Cysteine – 8%

- Yeast extract – 15%

- Thiamine – 0.5%

- Water – 200% (processing)

Conditions

- pH: 6.5–7.2

- Temp: 125–140°C

- Time: 45–90 min

- Slightly reducing atmosphere

Key Molecules

- 2-Furfurylthiol (coffee impact)

- 2-Methylpyrazine

- 2,3-Dimethylpyrazine

- 2-Acetylpyrrole

- Methional

2️⃣ COCOA Flavor Reaction System

Objective

Chocolate, nutty, brown, slightly fruity

Precursors

- Glucose

- Fructose

- Valine

- Leucine

- Phenylalanine

Formula

- Glucose – 35%

- Fructose – 15%

- Valine – 15%

- Leucine – 15%

- Phenylalanine – 10%

- Cocoa powder – 10%

Conditions

- pH: 6.0

- Temp: 120–135°C

- Time: 60 min

Key Molecules

- 2,3,5-Trimethylpyrazine

- 2-Phenylacetaldehyde

- 3-Methylbutanal

- 2-Acetylpyrazine

3️⃣ CHICKEN Flavor System

Objective

Meaty, brothy, roasted poultry

Precursors

- Ribose

- Cysteine

- Thiamine

- Glutamic acid

Formula

- Ribose – 30%

- Cysteine – 10%

- Hydrolyzed vegetable protein – 40%

- Glutamic acid – 15%

- Thiamine – 0.5%

Conditions

- pH: 6.5

- Temp: 110–125°C

- Time: 45 min

Key Molecules

- 2-Methyl-3-furanthiol

- Bis(2-methyl-3-furyl) disulfide

- Methional

- 2-Acetylthiazole

4️⃣ PORK Flavor System

Objective

Fatty, savory, slightly sweet roasted meat

Additions

- Ribose

- Cysteine

- Threonine

- Added pork fat

Formula

- Ribose – 25%

- Cysteine – 8%

- Threonine – 12%

- Pork fat – 20%

- Yeast extract – 30%

Conditions

- pH: 6.8

- Temp: 125–140°C

- Slight oxidation allowed

Key Molecules

- 2-Acetylthiazole

- 3-Methylbutanal

- Alkylpyrazines

- Lipid-derived aldehydes

5️⃣ BAKERY Flavor System

Objective

Fresh bread crust, toasted, nutty

Precursors

- Glucose

- Proline

- Glycine

- Yeast extract

Formula

- Glucose – 45%

- Glycine – 20%

- Proline – 15%

- Yeast extract – 20%

Conditions

- pH: 7.0

- Temp: 135–150°C

- Dry heating preferred

Key Molecules

- 2-Acetyl-1-pyrroline

- 2-Acetylpyrazine

- 2,3-Dimethylpyrazine

6️⃣ BEEF Flavor System

Objective

Deep roasted, steak, umami

Precursors

- Ribose

- Cysteine

- Methionine

- Creatinine

Formula

- Ribose – 30%

- Cysteine – 8%

- Methionine – 8%

- Creatinine – 5%

- Beef tallow – 20%

- HVP – 29%

Conditions

- pH: 6.5

- Temp: 125–145°C

- 60–90 min

Key Molecules

- 2-Methyl-3-furanthiol

- 2-Acetylthiazole

- Strecker aldehydes

- Alkylpyrazines

7️⃣ CHOCOLATE Flavor System

Objective

Milk chocolate, creamy cocoa

Precursors

- Lactose

- Glucose

- Valine

- Leucine

- Milk solids

Conditions

- pH: 6.3

- Temp: 120–135°C

Key Molecules

- 2,3,5-Trimethylpyrazine

- 2-Phenylacetaldehyde

- Maltol

- Isomaltol

8️⃣ CABBAGE Flavor System

Objective

Sulfurous, green, cooked brassica

Precursors

- Cysteine

- Methionine

- Glucose

Conditions

- pH: 6

- Temp: 105–115°C

- Short reaction (30–45 min)

Key Molecules

- Dimethyl trisulfide

- Methanethiol

- 3-Methylthiopropanal

9️⃣ POPCORN Flavor System

Objective

Buttery, toasted corn

Precursors

- Glucose

- Proline

- Diacetyl (added post-reaction)

Conditions

- pH: 7.2

- Temp: 140–150°C

- Dry reaction preferred

Key Molecules

- 2-Acetyl-1-pyrroline

- 2-Acetylpyrazine

- Diacetyl

🔟 MAPLE Flavor System

Objective

Maple syrup, caramelized sugar

Precursors

- Sucrose

- Fructose

- Threonine

Conditions

- pH: 5.5

- Temp: 115–130°C

Key Molecules

- Sotolon

- Maltol

- Cyclotene

1️⃣1️⃣ HONEY Flavor System

Objective

Floral caramel sweetness

Precursors

- Fructose

- Glucose

- Phenylalanine

Conditions

- pH: 4.5–5

- Temp: 100–120°C

Key Molecules

- Phenylacetaldehyde

- Hydroxymethylfurfural

- Norisoprenoids

🔬 Industrial Optimization Tips

- Ribose dramatically increases meaty impact vs glucose.

- Cysteine controls sulfur potency — >10% gives harsh burnt notes.

- Thiamine is powerful for meat — keep <1%.

- pH above 7 increases pyrazines.

- Slight oxygen improves roasted meat authenticity.

- Vacuum concentration post-reaction enhances intensity.

###